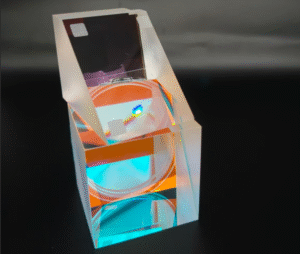

CO₂ laser mirrors are critical optical components used to reflect infrared laser beams, particularly those emitted at a wavelength of 10.6μm. They are commonly found in laser cutting machines, engraving systems, and even medical devices such as fractional CO₂ lasers.At Bote Optical, we offer precision-engineered CO₂ laser mirrors with outstanding reflectivity, thermal stability, and durability. Whether you need standard sizes or customized optics, we have the capability to manufacture and deliver optical mirrors tailored to your needs.

Types of CO₂ Laser Mirrors

Understanding the different types of CO₂ laser mirrors is key to selecting the right product for your application. Below is a comparison of common types:

| Mirror Type | Material | Reflectivity (@10.6μm) | Applications |

|---|---|---|---|

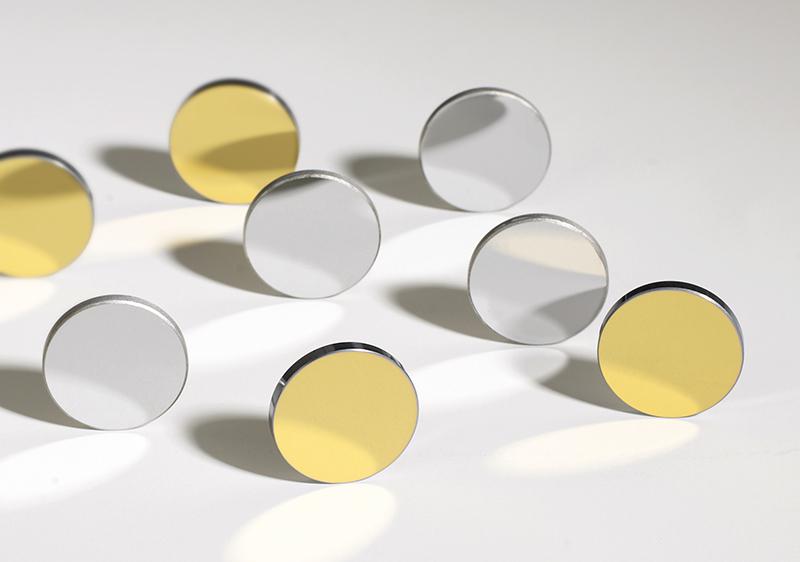

| Silicon (Si) Mirror | Monocrystalline Silicon | >99.5% | General cutting and engraving |

| Molybdenum (Mo) Mirror | Pure Molybdenum | ~98% | Harsh environments, no coating needed |

| Copper (Cu) Mirror | Oxygen-free copper | >99.5% (gold coated) | High-power laser applications |

Each type offers unique benefits:

- Silicon Mirrors: Lightweight, high reflectivity with a protective dielectric coating.

- Molybdenum Mirrors: Excellent scratch resistance and durability; ideal for dirty or abrasive environments.

- Copper Mirrors: Exceptional thermal conductivity; perfect for high-power CO₂ lasers.

🛠 Customization Available

We manufacture CO₂ laser mirrors in standard diameters (e.g., 20mm, 25mm, 30mm) or custom sizes based on your technical drawings. Anti-reflective and protective coatings can be applied per request.

- Inspection Equipment List and Metrology of Bote Optics

- Introduction of BOTE Key Equipment

- Catalog of Precision Optics

- Catalog of Imaging Optics

- ISO9001-2015 Certified

How to Focus a CO₂ Laser: Importance of Precision Mirrors

Correct focusing is essential for achieving precise cuts and engravings. The laser beam path typically involves multiple reflection points where CO₂ laser mirrors are used to direct the beam toward the focal lens.

Tips for optimal focus using CO₂ laser mirrors:

- Ensure mirrors are properly aligned using a beam alignment tool.

- Use high-reflectivity mirrors to reduce energy loss.

- Maintain cleanliness of all mirror surfaces.

🔧 Poor focusing often leads to power loss, burn marks, or incomplete cuts. Investing in high-performance CO₂ laser mirrors from Bote ensures consistent beam delivery and peak optical efficiency.

Applications of CO₂ Laser Mirrors

1. Industrial Cutting & Engraving

CO₂ laser mirrors are widely used in CNC laser machines for:

- Cutting acrylic, wood, rubber, leather

- Engraving glass, plastics, or coated metals

How to engrave glass with a CO₂ laser?

Use masking tape, reduce power, and increase speed to avoid cracking. A high-quality mirror ensures precise beam control and clean engraving lines.

2. Medical & Aesthetic Devices

Fractional CO₂ laser vs. carbon laser:

Fractional CO₂ lasers use a split-beam approach for skin resurfacing, while carbon lasers use a carbon-based gel to enhance absorption. Both require precision beam guidance, where mirror quality plays a vital role in treatment accuracy.

3. Scientific and Research Use

CO₂ laser mirrors are also critical in laboratory setups involving gas lasers, optical experiments, and mid-infrared spectroscopy.

Can a Laser Cut a Mirror?

While a laser can etch or damage a mirror’s surface, cutting through glass mirrors using a CO₂ laser is not recommended due to reflection risks and thermal cracking. However, mirrors made for lasers, such as dielectric-coated optics, are designed to handle intense IR beams safely and efficiently.

Does CO₂ Laser Really Work?

Absolutely. CO₂ lasers are proven tools in both industrial and medical sectors. The effectiveness of a CO₂ laser depends not just on the power source, but also on the quality of its optics—especially the mirrors that guide the beam.

🧠 At Bote Optical, we optimize our CO₂ laser mirrors for:

- High Reflectivity

- Thermal Stability

- Durability under High-Power IR

Why Choose Bote for CO₂ Laser Mirrors?

🔹 In-house polishing, coating, and inspection

🔹 Singapore-based logistics advantage

🔹 Engineering support for optical system design

🔹 Export-compliant supply of infrared optics globally

Our factory supports low to medium volume production, ideal for both custom R&D and OEM applications. Visit our Optical Manufacturing Capabilities page to learn more.

FAQs

Q1: How often should I replace CO₂ laser mirrors?

A: Generally every 3–6 months, depending on usage and maintenance. Inspect regularly for scratches or coating wear.

Q2: Can I clean CO₂ laser mirrors?

A: Yes. Use lens cleaning tissue with isopropyl alcohol. Avoid touching the coated surface with fingers.

Q3: What is the typical reflectivity of a good CO₂ laser mirror?

A: >99.5% reflectivity at 10.6μm is considered optimal for most applications.

Q4: Do you provide coated and uncoated mirrors?

A: Yes. We offer dielectric-coated silicon mirrors, uncoated molybdenum mirrors, and gold-coated copper mirrors.

Contact Us for Custom CO₂ Laser Mirrors

If you’re seeking high-precision CO₂ laser mirrors with fast delivery and technical support, contact us today:

📧 Email: [email protected]

🌐 Website: www.bote.com.sg

📍 Headquarters: Singapore, with full support from our Nanjing production facility