What is GaAs (Gallium Arsenide)?

Gallium Arsenide (GaAs) is a compound semiconductor material made from gallium and arsenic. It is widely used in infrared optics, semiconductors, and high-speed electronics due to its excellent optical and electrical properties.

Key Properties of GaAs:

| Property | Value |

|---|---|

| Chemical Formula | GaAs |

| Transparency Range | 2 µm – 16 µm |

| Refractive Index (@10µm) | ~3.3 |

| Hardness (Knoop) | 750 |

| Density | 5.32 g/cm³ |

| Thermal Expansion | 5.8 x 10⁻⁶ /K |

| Crystal Structure | Zinc Blende |

GaAs vs ZnSe Lenses: Which to Choose?

GaAs and Zinc Selenide (ZnSe) are both popular infrared (IR) materials, but they serve different needs.

| Feature | GaAs | ZnSe |

|---|---|---|

| Transmission Range | 2–16 µm | 0.6–20 µm |

| Refractive Index | ~3.3 | ~2.4 |

| Durability | High hardness | Softer, more prone to scratches |

| Cost | Generally higher | More cost-effective |

| Toxicity | Low in finished optics | Non-toxic |

| Application Focus | CO₂ lasers, FTIR, imaging optics | CO₂ lasers, thermal imaging |

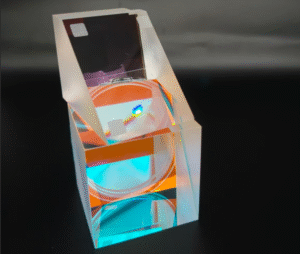

📷 [Insert Image: Side-by-side photo of GaAs and ZnSe lenses with labeled dimensions and coatings]

GaAs is often chosen when high thermal stability and durability are critical—especially in military-grade or harsh environment infrared systems.

Why Use a GaAs Lens?

1. Infrared Imaging & FTIR Systems

GaAs lenses provide clear transmission in mid- to far-infrared wavelengths, making them ideal for spectroscopy and thermal imaging systems.

2. Laser Applications

GaAs is resistant to laser damage and works well in high-power CO₂ laser focusing systems.

3. Semiconductor Equipment

GaAs’s electrical conductivity also allows integration into optoelectronic systems.

GaAs Focus Lenses & Custom Options at Bote

At Bote Singapore, we manufacture and inspect custom GaAs focus lenses designed for precision IR systems.

🔧 Our Capabilities:

- Full in-house lens grinding and polishing

- DLC or AR coating on request

- Diameter tolerance: ±0.02 mm

- Surface accuracy: Up to λ/10

- Infrared spectrometer-based transmission testing

📷 [Insert Image: IR transmission graph of GaAs lenses from Bote]

📷 [Insert Image: GaAs lens in inspection under interferometer]

We also offer lens design support, from material selection to final system integration.

GaAs Wafers and Raw Substrates

In addition to finished lenses, Bote supports orders for precision-ground GaAs wafers:

- Diameter: 10 mm – 150 mm

- Surface: Double-side polished

- Parallelism: < 1 arc min

- Flatness: < 1 µm

These are ideal for further processing into micro-optical elements or integration into photonic devices.

What is GaAs Refractive Index?

The refractive index of Gallium Arsenide is wavelength-dependent. At 10 µm, it is approximately 3.3.

| Wavelength (µm) | Refractive Index (n) |

|---|---|

| 2 | 3.88 |

| 4 | 3.49 |

| 8 | 3.34 |

| 10 | 3.30 |

| 12 | 3.29 |

📷 [Insert Image: GaAs refractive index curve vs wavelength]

High refractive index makes GaAs ideal for compact, short focal length IR lenses.

Gascan Lens Replacement vs GaAs Lens

Some users mistakenly search for “Gascan lens replacement” when they mean GaAs lenses. Be sure to confirm the intended use. Gascan usually refers to Oakley eyewear; GaAs lenses are used in industrial and scientific equipment.

Why Choose Bote for Your GaAs Lens Supply?

- 🌏 Singapore-based Export: Fast, ITAR-free global delivery

- 🛠️ Customized Engineering: OEM lens solutions

- 🔬 Advanced Metrology: Zygo interferometers, IR transmission testing, surface roughness profiling

- 📦 Flexible MOQ: From single prototypes to bulk orders

We understand the precision and consistency required in optical systems, especially in the IR spectrum.

Conclusion

GaAs lenses offer exceptional performance in the infrared region, particularly where high durability and thermal stability are essential. At Bote, we specialize in custom GaAs optics that meet strict optical tolerances and performance standards. Whether you need lenses, windows, or wafers, our team supports your project from design to delivery.

📩 Contact us today at www.bote.com.sg to request a quote or discuss your IR optics needs.