Introduction: What Is Interferometry?

Interferometry is a powerful optical measurement technique that uses the principle of interference—where two or more light waves superimpose to extract precise dimensional, angular, or surface information. It is widely used in physics, metrology, fiber optics, astronomy, and manufacturing quality control.

At Bote Optics, we supply custom lenses, prisms, windows, and coatings that are compatible with high-precision interferometry systems, helping engineers and scientists push the limits of measurement accuracy.

Definition of Interferometer in Physics

An interferometer is an optical instrument that splits a beam of light into two or more paths, reflects them, and then recombines them to form interference fringes. These fringes provide data about the optical path difference, which can reveal extremely small changes in distance, refractive index, surface flatness, or displacement.

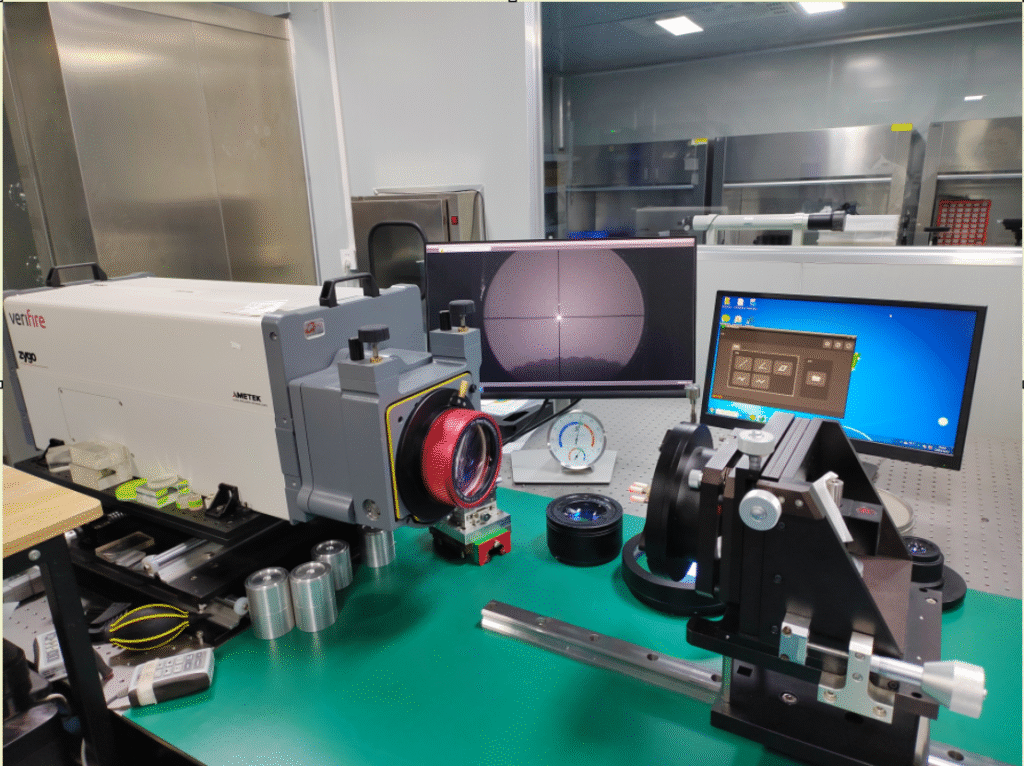

What Is Interferometry in Metrology?

In metrology, interferometry is essential for high-precision measurements such as:

- Flatness testing of optical components

- Surface profile measurement of lenses or wafers

- Alignment of mechanical components

- Refractive index and thickness analysis

Interferometry enables nanometer-level resolution, far beyond the capabilities of traditional measurement tools.

Types of Interferometers

| Type | Key Application | Feature |

|---|---|---|

| Michelson Interferometer | General optics, FTIR | Simple design, high sensitivity |

| Mach-Zehnder Interferometer | Flow dynamics, plasma research | Suited for visualization |

| Fabry–Pérot Interferometer | Spectroscopy, laser tuning | High resolution for spectral lines |

| Twyman-Green Interferometer | Surface testing | Ideal for reflective optics |

| Fizeau Interferometer | Flatness testing | Often used in production lines |

| Laser Interferometers | Precision displacement | Nanometer-scale accuracy |

For optical metrology systems requiring custom windows, plano optics, or beam splitters, Bote Optics can manufacture components to match your interferometer’s design and wavelength requirements.

What Is an Ultrasonic Interferometer?

An ultrasonic interferometer operates on sound waves rather than light. It is primarily used to measure the velocity of ultrasonic waves in a medium, often in academic research or materials science.

While it shares the basic principle of wave interference, its setup differs from optical interferometry and involves piezoelectric transducers and acoustic media.

What Is the Purpose of Interferometry?

Interferometry’s primary purpose is high-resolution measurement. Applications include:

- Astronomy: Combining data from multiple telescopes to simulate larger apertures.

- Semiconductor: Wafer flatness and thickness measurement.

- Engineering: Vibration and strain analysis.

- Optics: Quality assurance for lenses and windows.

Bote’s optical substrates and coatings are designed to support high-reflectance, low-absorption requirements necessary for precision interferometry environments.

Laser Interferometer Price and Considerations

Laser interferometers can range from a few thousand to tens of thousands of USD, depending on specifications like:

- Wavelength stability

- Displacement range

- Vacuum compatibility

- Environmental isolation

When sourcing components for a laser interferometer, the quality of the optical surfaces and coatings is critical. Contact Bote Optics to discuss how we can assist with high-precision flat optics, AR/DLC coatings, and low-scatter substrates.

Optical Interferometer Applications in Industry

- Precision machine alignment

- Test of large mirrors and flats

- Verification of optical design prototypes

- Calibration of coordinate measuring machines (CMM)

Bote supports R&D labs and OEMs with custom interferometer-grade optics such as large-aperture plano windows, reference flats, and test plates.

When Was the Interferometer Invented?

The concept of optical interference dates back to Thomas Young’s double-slit experiment in the early 1800s. However, the first true interferometer—the Michelson Interferometer—was invented in 1881 by Albert A. Michelson. His invention led to one of the most famous experiments in physics, the Michelson-Morley experiment, which contributed to Einstein’s theory of relativity.

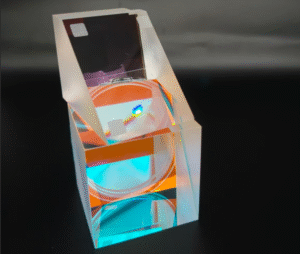

Bote Optics for Interferometry Applications

We offer:

- High-flatness optical flats (λ/10 or better)

- Beam splitter plates

- Large-aperture plano windows

- Ultra-low surface roughness polishing

- Custom materials (fused silica, BK7, sapphire, etc.)

- Coatings optimized for laser wavelengths (1064nm, 1550nm, etc.)

All optics are manufactured with tight tolerance control, and we support OEM, academic, and government metrology projects.

Common Questions about Interferometry

Q: What wavelength is best for interferometry?

A: It depends on the application, but common wavelengths include 632.8 nm (HeNe laser), 1064 nm (Nd:YAG), and 1550 nm (telecom-grade).

Q: Can interferometry measure surface roughness?

A: Yes, certain types of interferometers like white light interferometers can measure nanometer-level surface roughness.

Q: What’s the difference between white light and laser interferometry?

A: Laser interferometry offers high coherence and accuracy over long distances, while white light interferometry is better suited for surface profiling due to its low coherence.

Conclusion: Precision Demands Interferometry—and Reliable Optics

Interferometry plays a vital role in modern science and engineering, enabling ultra-precise measurements that conventional tools cannot achieve. If you’re building or upgrading an interferometry setup, make sure your optical components meet the required flatness, coating, and dimensional specs.

Explore our custom optics manufacturing capabilities and request a quote tailored to your interferometer’s needs.

Need Interferometer-Grade Optics?

📩 Contact Bote Optics for expert support and customized solutions.