Aspheric lenses have revolutionized modern optics by offering enhanced performance, compactness, and improved aberration correction over traditional spherical lenses. In this guide, we explore the meaning of aspheric lenses, their design principles, types, advantages and disadvantages, and applications. Whether you’re an optical designer, a systems integrator, or a curious tech enthusiast, understanding aspheric optics is essential.

What Is an Aspheric Lens?

An aspheric lens (short for “aspherical”) features a surface profile that deviates from a simple sphere or cylinder. The curvature varies radially from the optical axis, which allows better control over optical aberrations. In contrast, a spherical lens has a constant radius of curvature.

Aspheric meaning: The term “aspheric” comes from “a-” meaning “not” and “spheric,” indicating that the lens is not part of a perfect sphere.

Aspheric Lenses vs. Spherical Lenses

| Property | Spherical Lenses | Aspheric Lenses |

|---|---|---|

| Surface curvature | Constant | Varies across surface |

| Aberration correction | Limited | Superior |

| Weight | Heavier (more elements) | Lighter (fewer elements) |

| Cost | Lower | Higher (complex to make) |

| Image quality | Moderate | High (especially off-axis) |

Are aspheric lenses better? Generally, yes. Especially in applications where weight, size, and image clarity are critical—such as in smartphones, AR/VR, high-precision instruments, and aerospace.

Types of Aspheric Lenses

- Plano-Aspheric Lenses: Flat on one side, aspheric on the other. Ideal for collimating or focusing laser beams.

- Convex Aspheres: Positive focal length, often used in focusing applications.

- Concave Aspheres: Negative focal length, useful in beam expansion or divergence control.

- Double Aspheric Lenses: Aspheric on both sides. These offer even better aberration correction and compact optical systems.

Are double aspheric lenses worth it? Yes—especially when ultra-high performance is required. Though costlier, they reduce system complexity and size significantly.

Aspheric Lens Design & Equation

Aspheric lens design involves advanced surface profiling beyond the parabolic or spherical form. The general aspheric surface profile is described by:

Where:

- is the sag (surface profile)

- is the radial coordinate

- is the radius of curvature

- is the conic constant

- are higher-order aspheric coefficients

Designing these lenses requires precise modeling and CNC or MRF-based fabrication.

Aspheric Lenses Advantages and Disadvantages

Advantages

- Aberration correction (especially spherical aberration and coma)

- Weight and space savings (fewer elements needed)

- Improved light throughput

- Ideal for compact optical systems

Disadvantages

- Higher price (due to manufacturing complexity)

- More difficult to test and polish

- Sensitive to alignment errors

Aspheric Lenses in Practice

Applications

- Consumer electronics: Smartphone cameras, VR headsets

- Medical optics: Endoscopes, ophthalmic instruments

- Laser systems: Beam shaping, focusing

- Astronomy & telescopes: Correcting off-axis aberrations

High Index Aspheric Lenses

High-index materials (n > 1.7) can reduce lens thickness while maintaining focal power, useful in miniaturized systems. However, they may increase chromatic aberration if not properly corrected.

Aspheric vs. Pancake Lenses

Pancake lenses are designed for slim form factors, especially in portable cameras. Some incorporate aspheric lens elements to improve image quality while maintaining a low profile.

Are Aspheric Lenses Expensive?

Aspheric lenses price depends on:

- Material (glass, plastic, IR materials)

- Size and surface accuracy

- Quantity (custom or volume production)

Plastic-molded aspheres are economical for mass production, while precision glass or IR-grade lenses (used in military or industrial optics) are higher in price.

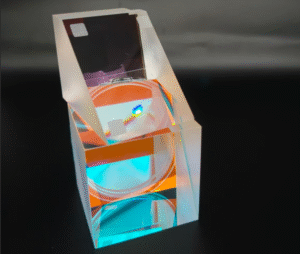

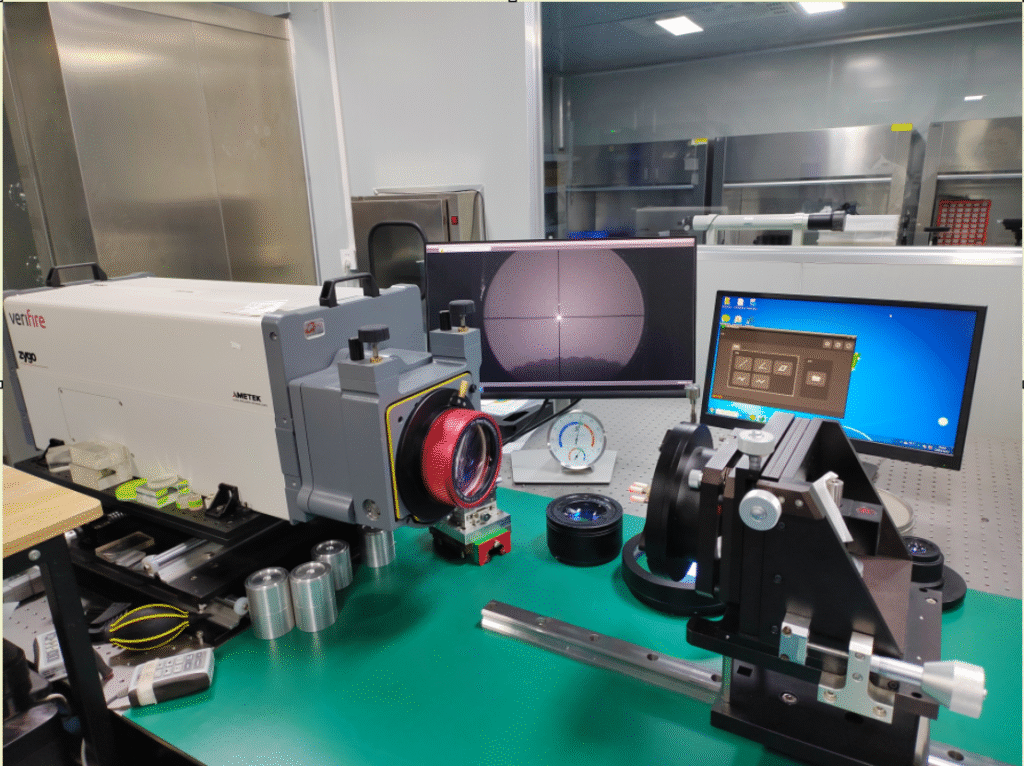

For custom aspheric optics, Bote Optics offers tailored manufacturing, surface metrology, and coating services. We support UV to IR wavelength ranges and use interferometry, profilometry, and CNC polishing to meet tight tolerances.

- AR coatings and broadband multilayer coatings

Interferometer by Zygo

Interferometer by Zygo

Frequently Asked Questions (FAQ)

Q1: What are diffraction limited aspheres?

A: These are lenses designed and fabricated to perform at the theoretical limit of resolution, free of major aberrations.

Q2: What is the difference between aspheric and double aspheric lenses?

A: Double aspheric lenses have aspheric surfaces on both sides, offering better aberration correction and thinner form factors.

Q3: Can I request custom coatings on aspheric lenses?

A: Yes. At Bote Optics, we offer AR, IR, and reflective coatings tailored to your wavelength and environmental needs.

Q4: Are aspheric lenses better for eyeglasses?

A: Yes. They provide thinner, lighter lenses with better peripheral vision correction compared to spherical lenses.

Why Choose Bote Optics for Custom Aspheric Lenses?

- Over 15 years of precision optics manufacturing

- In-house CNC, MRF, and interferometric metrology

- Global service from Singapore & Nanjing

- Wide material selection: N-BK7, ZnSe, Sapphire, Chalcogenides, and more

- Custom assembly and coating available

Contact us today to discuss your aspheric lens requirements.

Related Reads:

Boost your optics performance with custom aspheric lenses—engineered for precision, designed for excellence.