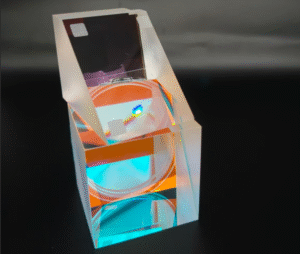

Introduction: What is a Silicon Mirror?

Silicon mirrors are highly reflective optical components made from crystalline silicon or silicon carbide (SiC), used widely in infrared systems, lasers, defense optics, and space applications. These mirrors provide high reflectivity, low thermal expansion, and excellent mechanical stability, making them ideal for high-performance optical systems.

At Bote Optical Singapore, we design and manufacture custom silicon and silicon carbide mirrors with precision polishing, various coating options, and exceptional flatness to meet the strict demands of optical engineers across industries.

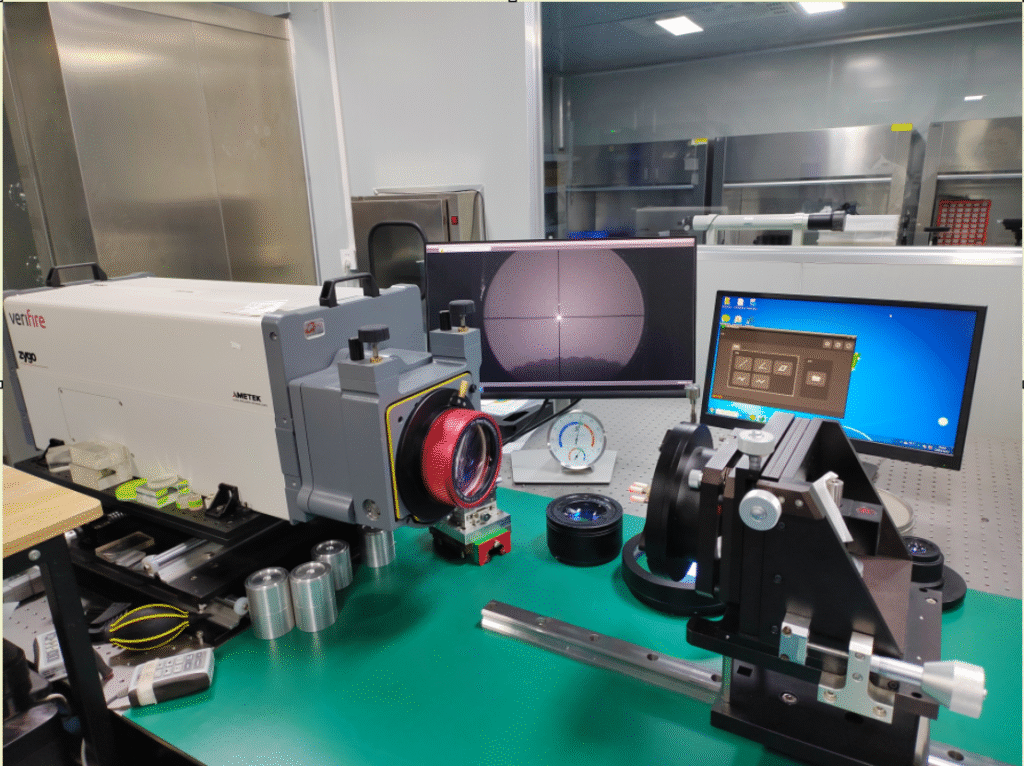

- Inspection Equipment List and Metrology of Bote Optics

- Introduction of BOTE Key Equipment

- Catalog of Precision Optics

- Catalog of Imaging Optics

- ISO9001-2015 Certified

Silicon vs. Silicon Carbide Mirrors: Comparison Table

| Feature | Silicon (Si) Mirror | Silicon Carbide (SiC) Mirror |

|---|---|---|

| Density | ~2.33 g/cm³ | ~3.21 g/cm³ |

| Reflectivity (Uncoated) | Moderate in IR | High in IR with coatings |

| Thermal Expansion | Low | Very low (almost zero) |

| Mechanical Strength | Good | Excellent |

| Thermal Conductivity | High | Extremely high |

| Best Used For | IR lasers, optics | Space optics, aerospace, lightweight systems |

| Surface Finish | Polished to λ/10 or better | Polished or lightweighted honeycomb |

✅ Both can be coated with protected gold, dielectric, or enhanced aluminum coatings for optimal performance.

Silicon Carbide Mirrors – Lightweight and Strong

Silicon carbide mirrors are well known for their ultra-lightweight and high stiffness-to-weight ratio. This makes them a top choice for:

- Space telescopes

- High-speed scanning mirrors

- Aerospace and satellite systems

- High-power laser beam delivery

🔍 Silicon Carbide Weight Advantage

Compared to traditional glass or metal substrates, silicon carbide can reduce mirror weight by over 50% without compromising stability. This makes it particularly beneficial in airborne or mobile optical systems where minimizing inertia is crucial.

Silicon Mirror Optical Properties

| Property | Value |

|---|---|

| Refractive Index (at 10.6 µm) | ~3.42 |

| Transparency Range | 1.2 µm – 7 µm (limited transmission) |

| Reflectivity (with Gold coating) | >98% at 8–12 µm |

| Surface Roughness (Polished) | <1 nm RMS (optional ultra-polished) |

Silicon mirrors are often used in CO₂ laser systems (10.6 µm), where their thermal resilience and mirror flatness are critical.

Applications of Silicon and Silicon Carbide Mirrors

Silicon-based mirrors are used in various fields, including:

- ✅ CO₂ and mid-IR laser systems

- ✅ Thermal imaging devices

- ✅ Spectroscopy and metrology

- ✅ Defense and target acquisition

- ✅ Spaceborne optical instruments

Silicon carbide is especially valuable where mechanical strength, lightweight structure, and thermal resistance are critical, such as satellite payloads or scanning LIDAR systems.

What Is Silicon Carbide Used In?

Silicon Carbide (SiC) isn’t limited to optics. It is widely used in:

- Semiconductors & power electronics

- High-temperature gas turbines

- Abrasives and ceramics

- Automotive parts

In optics, SiC excels due to its low coefficient of thermal expansion (CTE) and high thermal conductivity.

Are There Disadvantages of Silicon Carbide?

While silicon carbide offers many advantages, there are a few limitations to consider:

- ❌ More difficult to polish compared to glass

- ❌ Higher fabrication costs due to complex processing

- ❌ Surface can be brittle if mishandled

However, at Bote Optical, we overcome these challenges with precision grinding, super-polishing techniques, and strict QC protocols, ensuring every mirror meets your spec.

Custom Coating Options Available

We provide high-reflectivity coatings tailored to your wavelength:

| Coating Type | Reflectivity Range | Best For |

|---|---|---|

| Protected Gold (Au) | 97–99% @ 8–12 µm | Infrared / CO₂ lasers |

| Dielectric IR Coating | 99%+ @ design wavelength | High-power lasers |

| Enhanced Aluminum | 90–96% (broadband) | Visible to near-IR |

Let us know your application range and we’ll recommend the best coating.

Why Choose Bote Optical for Silicon Mirrors?

- 🇸🇬 Singapore-based QC & logistics

- ⚙️ Custom substrate sizes & thickness

- 🔍 High surface accuracy: λ/10 or better

- 🛡️ Durable coatings and protective handling

- 🌐 Serving clients globally with export-ready documents

Visit our full capabilities at www.bote.com.sg

Frequently Asked Questions (FAQ)

Q1: What are the benefits of silicon carbide mirrors over glass?

A: Silicon carbide mirrors are significantly stronger and lighter than glass, ideal for space or moving systems.

Q2: Do you offer lightweighted silicon mirrors?

A: Yes. We provide both solid and lightweighted (honeycomb structured) mirrors depending on your weight and thermal requirements.

Q3: Can I request a custom mirror size or curvature?

A: Absolutely. Bote Optical offers full customization on diameter, thickness, flatness, and surface coating.

Q4: How are these mirrors packaged and shipped?

A: All mirrors are packed in anti-static, shock-proof cases with moisture control. Export compliance is ensured.

Ready to Order or Request a Custom Quote?

📧 Email: [email protected]

🌐 Website: www.bote.com.sg

📍 Based in Singapore | Export globally

Get in touch today to discuss your silicon mirror or silicon carbide mirror project. We’ll help you meet the tightest tolerances and strictest application demands.